The metal substrate (steel or aluminium) is delivered in coil form from the rolling mill. Coil weight varies from 5-6 tons for aluminium and up to 20 tons for steel.

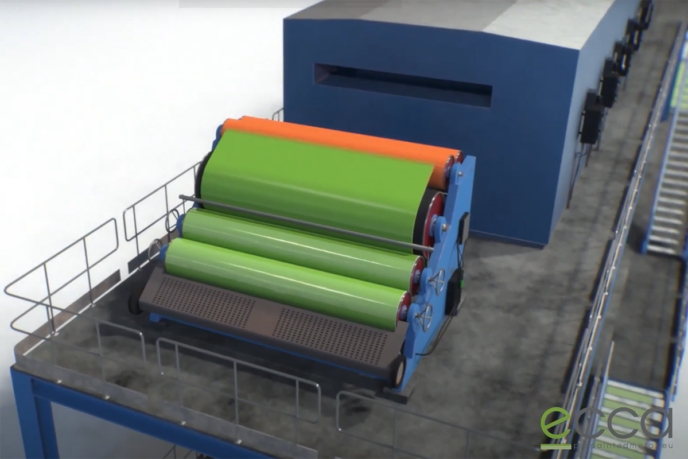

The coil is positioned at the beginning of the line, and then unwound at a constant speed, passing through the various pre-treatment and coating processes before being recoiled. Two strip accumulators found at the beginning and the end of the line enable the work to be continuous, allowing new coils to be added (and finished coils removed) by a metal stitching process without having to slow down or stop the line.

The following steps take place on a modern coating line:

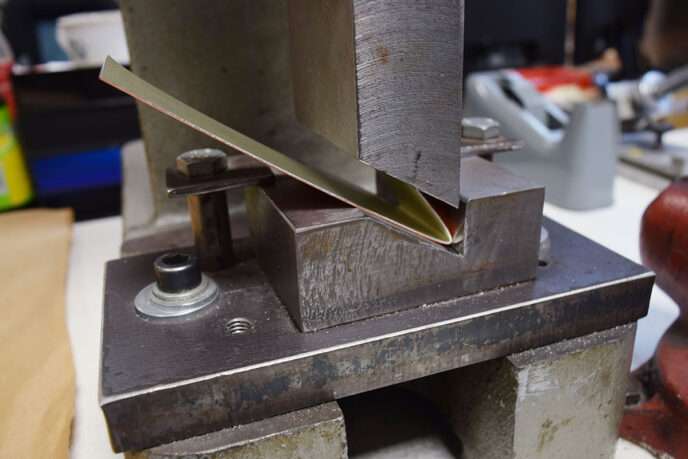

- Mechanical stitching of the strip to its predecessor

- Cleaning the strip

- Surface treatment by chemical conversion

- Drying the strip

- Application of primer on one or both sides

- Passage through the first curing oven (between 15 to 60 seconds)

- Cooling down the strip

- Coating the finish on one or both sides

- Passage through the second curing oven (between 15 to 60 seconds)

- Cooling down to room temperature

- Rewinding of the coated coil.

In addition to the application of organic coatings, the line is also used to apply laminating films.

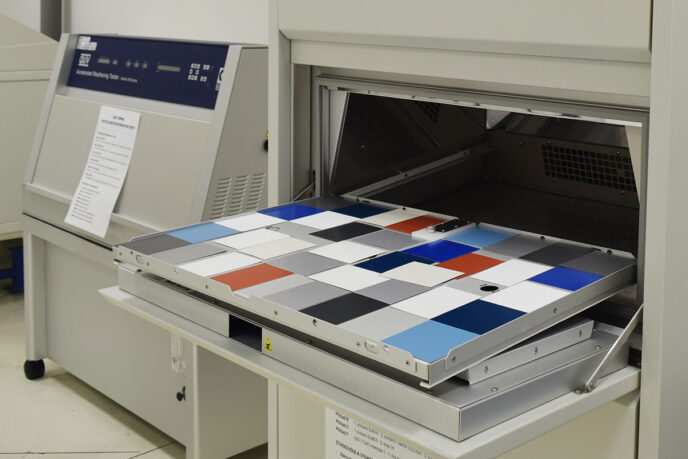

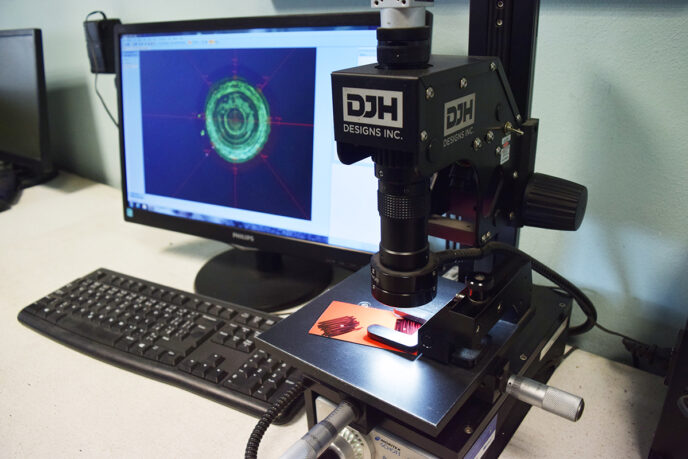

Both coated and laminated sheets have high resistance to climatic, mechanical and chemical influences. We test all of this in laboratories as well as in real conditions.